SUSTAINABILITY IS A NATURAL PART OF OUR BUSINESS

We believe that sustainable and profitable growth is key to the success of our brand and that our continuous work on sustainability will improve our products and services to the benefit of our customers. Our sustainability strategy is aligned with the UN Sustainable Development Goals and the Paris Agreement and is a fully integrated and natural part of our business.

RECYCLABLE TO 91%

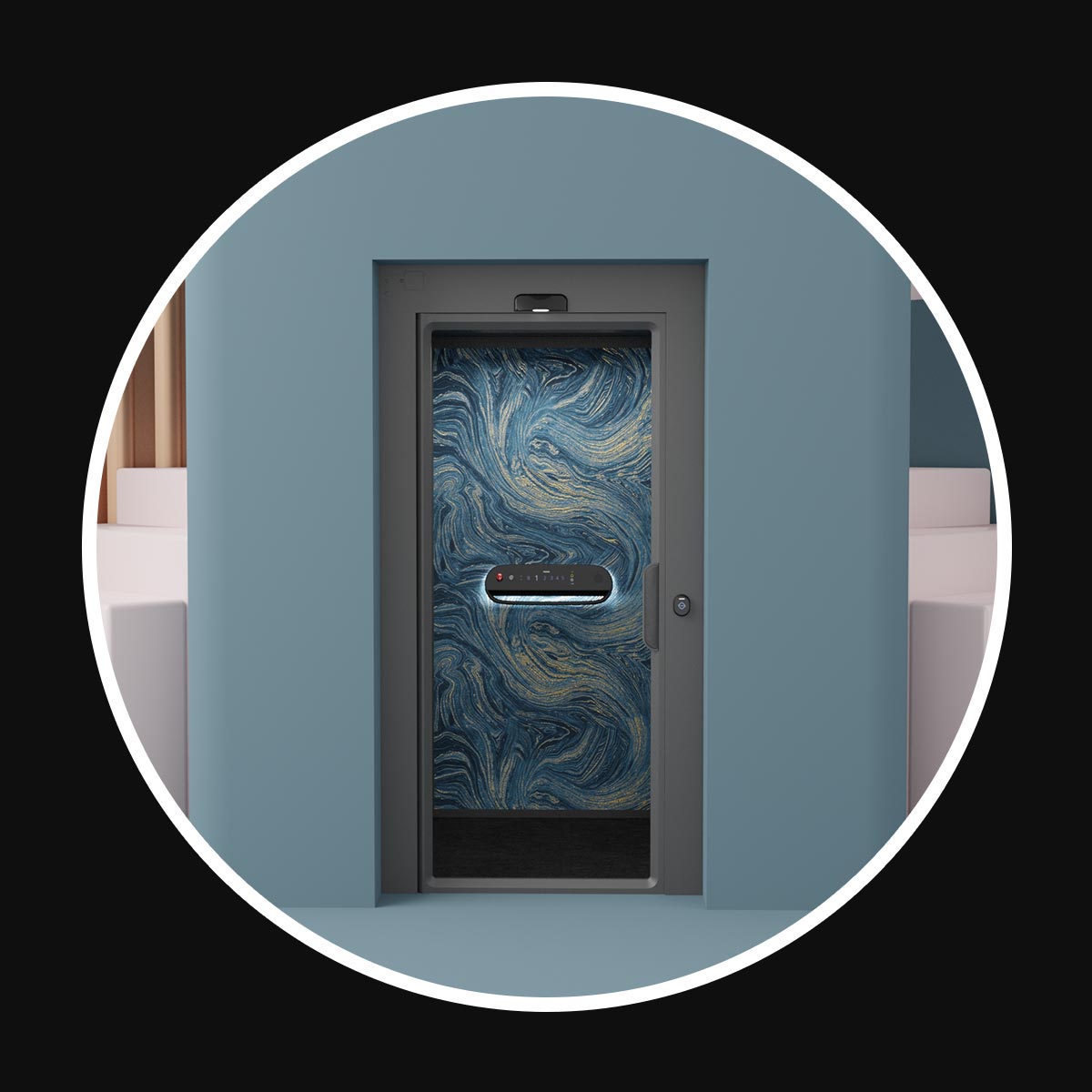

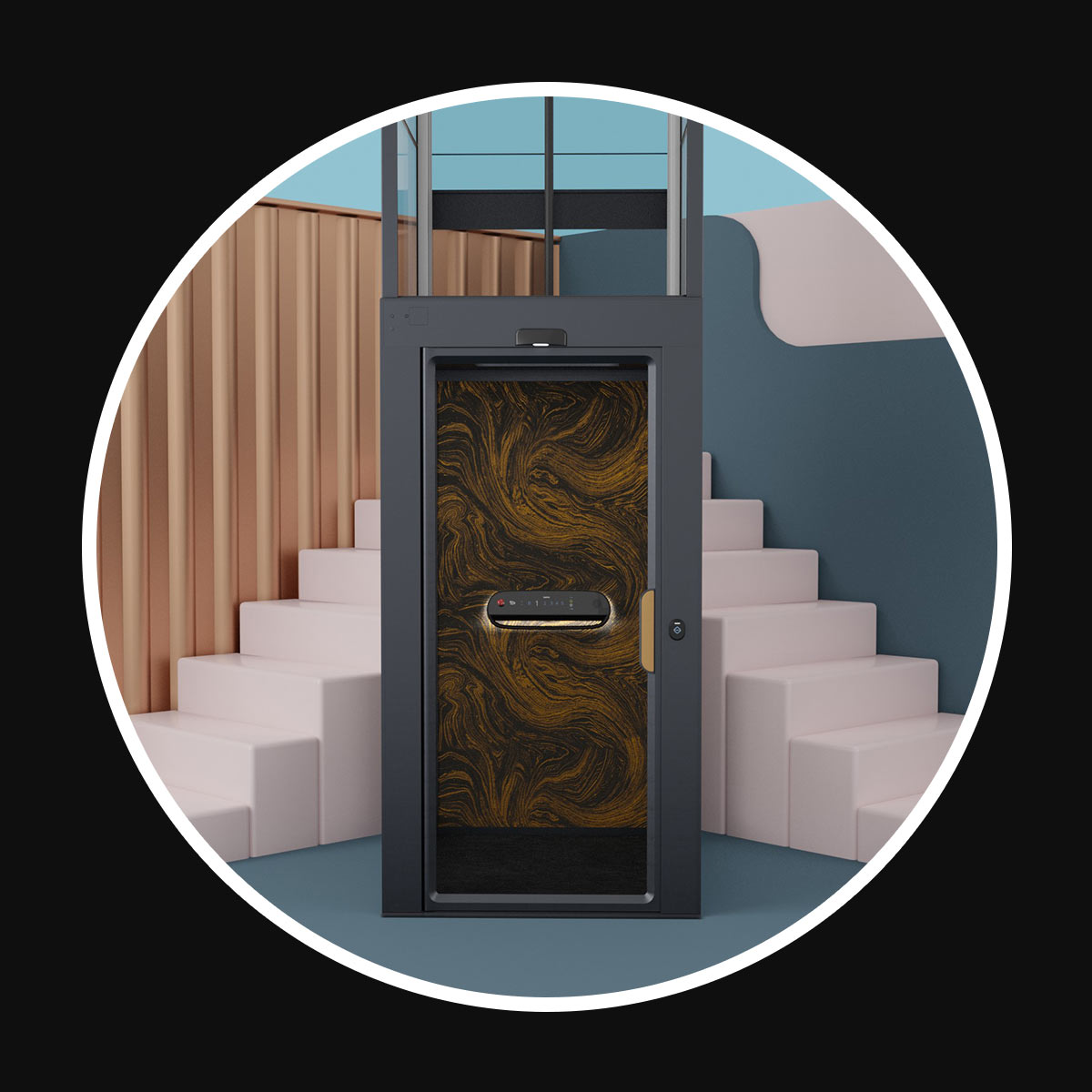

Our most popular platform lift, the Kalea A4 Primo, has a calculated lifetime of 25 years* and is recyclable to 91%.

SAFETY COMES FIRST

The health and safety of our employees, partners and customers are top priorities and a prerequisite for our business.

PRODUCT LIFECYCLE

Kalea offers a wide range of upgrade and modernisation kits to make it easy for you to extend the lifecycle of your lift.

ENERGY LABEL A

The EcoSilent drive system reduces the energy consumption of the lift by 45% and allows our lifts to carry Energy Label A.

SUSTAINABILITY PILLARS

Safety – Zero harm to people

Business – Sustainable business advantage

Planet – Responsible for a higher purpose

People – Make the difference

Ethics – Values matter

CODE OF CONDUCT

Our employees, business partners and suppliers receive training on our Codes of Conduct for employees and suppliers.

Equal treatment

Work rights

Business integrity

SUSTAINABILITY REPORT

Kalea Lifts is a brand owned by the Cibes Lift Group. The sustainability report covers all entities included in our consolidated financial statements. The report has been prepared in accordance with the core option of the Global Reporting Initiative Standards (GRI).

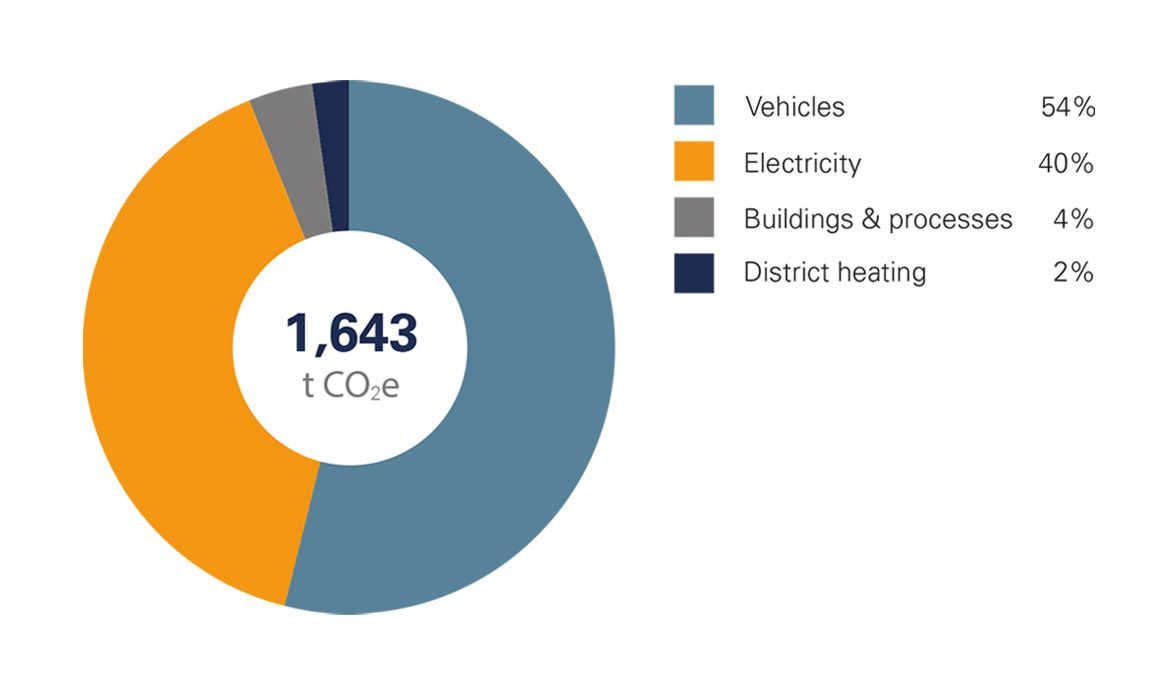

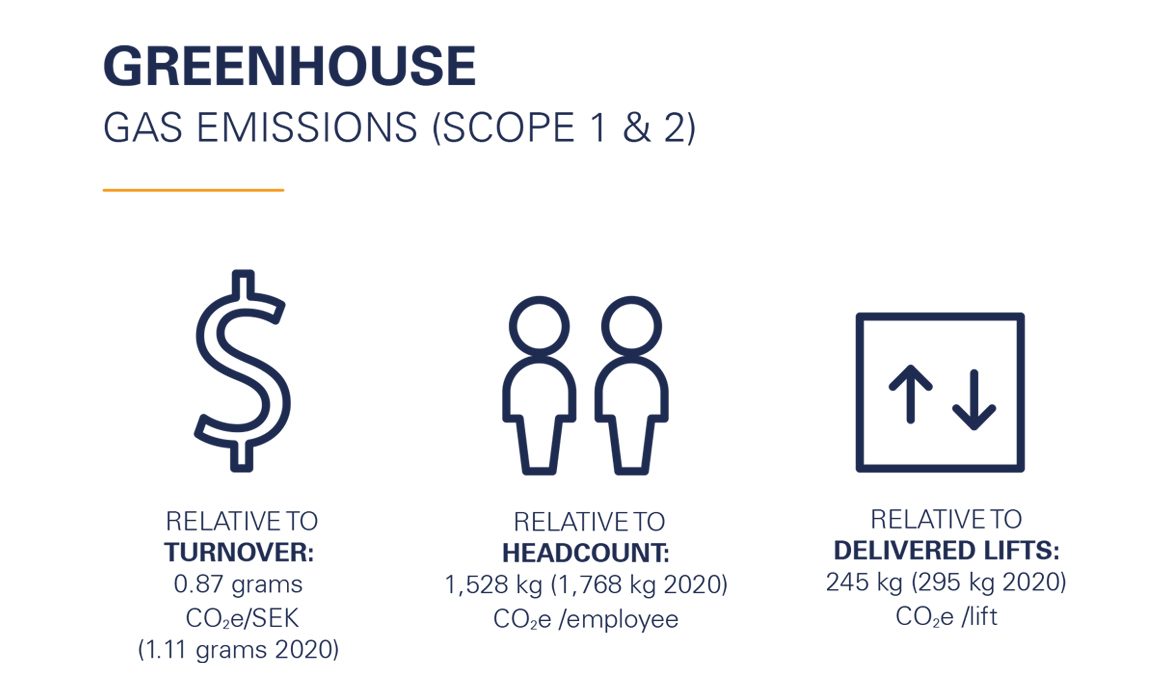

REDUCING OUR CO2 EMISSIONS

Starting with scope 1 & 2, our ambition is to reduce the emissions by 30% by 2025 compared to a 2021 baseline. Electricity and vehicles account for 94% of these emissions, which means that we need to focus on reducing our use of electricity and fuels and convert to green alternatives in order to reduce our carbon footprint.

WORKING FOR CIRCULARITY

In France, we have started to collect circuit boards returned under warranty. The idea is to send the circuit boards that can be saved back to the supplier to be repaired instead of ordering new ones. This is an initiative that can be rolled out to all companies of the group to increase circularity and reduce CO2 emissions.

– Clément Rabahi, Country Manager France

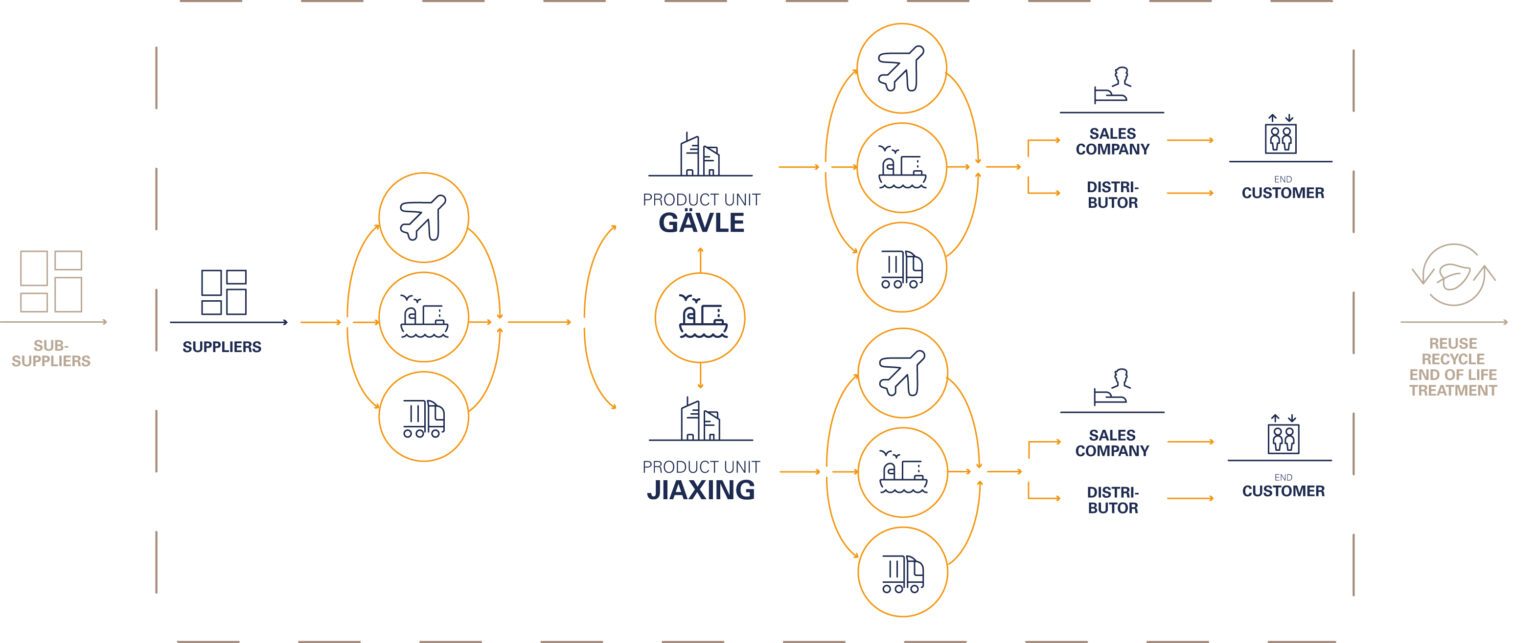

ANALYSING OUR VALUE CHAIN

We have set ourselves ambitious targets because we understand that our customers and stakeholders have high expectations on us to deliver products and services that are sustainable throughout the entire value chain. Having production facilities in both Sweden and China is a great advantage which not only brings us closer to our customers and suppliers but opens opportunities to increase local sourcing and reduce transport emissions.